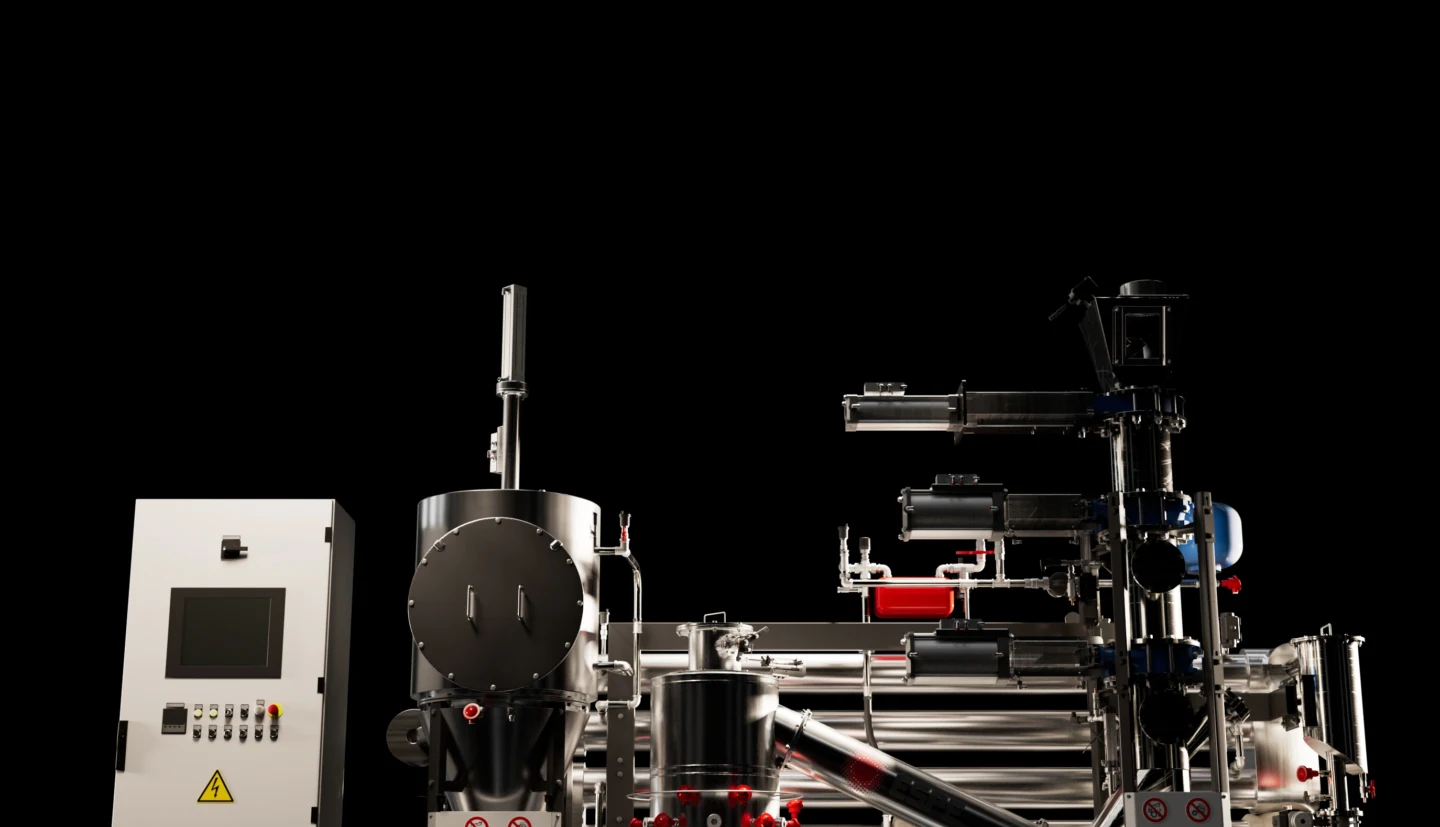

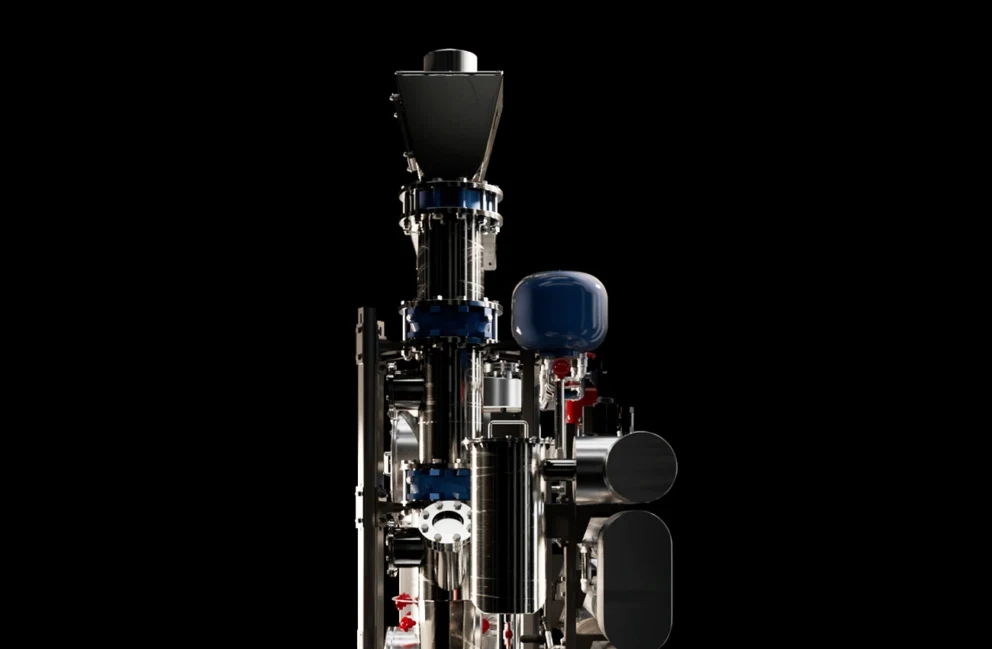

CHiP50 biomass cogenerator

CHiP50 is the Espe cogenerator intended for SMEs in search of a single solution to meet their thermal and electrical energy needs.

This is a system designed to obtain the highest possible efficiency with a relatively modest amount of fuel (wood chips), achieving a significant reduction in waste and optimizing the investment required for its implementation.

Every single component of the CHiP50 cogenerator is created, tested and assembled in our factory at Grantorto (Padua), drawing on forty years experience in the design and construction of electrical and energy systems. Prior to delivery, moreover, we test the overall operation of the cogenerator and check that the electrical, mechanical and safety parameters are all correct.

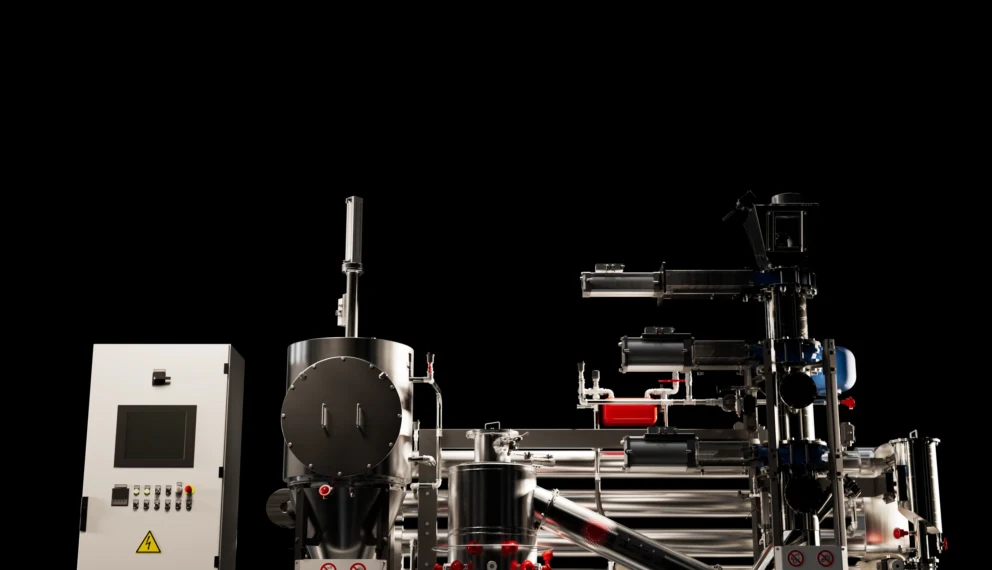

Advanced technology for optimum performance

Pyrogasification process: the CHiP50 system uses high temperature pyrogasification to bring about an effective conversion process without the need for additional filters.

Operational stability: advanced technology ensures stable and safe operation even when the system is kept running for lengthy periods.

Simplicity and maintenance: with its optimized structure, the CHiP50 cogenerator requires minimal maintenance and will operate for many hours without interruption.

Technical information

How the CHiP50 works

Efficiency, power and savings

Technical information CHiP50

- Special steels: three different types of steel are used to ensure optimum strength in every part of the reactor.

- Durability: selected materials and careful design enable the machine to withstand high temperatures and provide extended service life

- Optimized ROI: robust construction and low maintenance combine to ensure a quick return on investment.

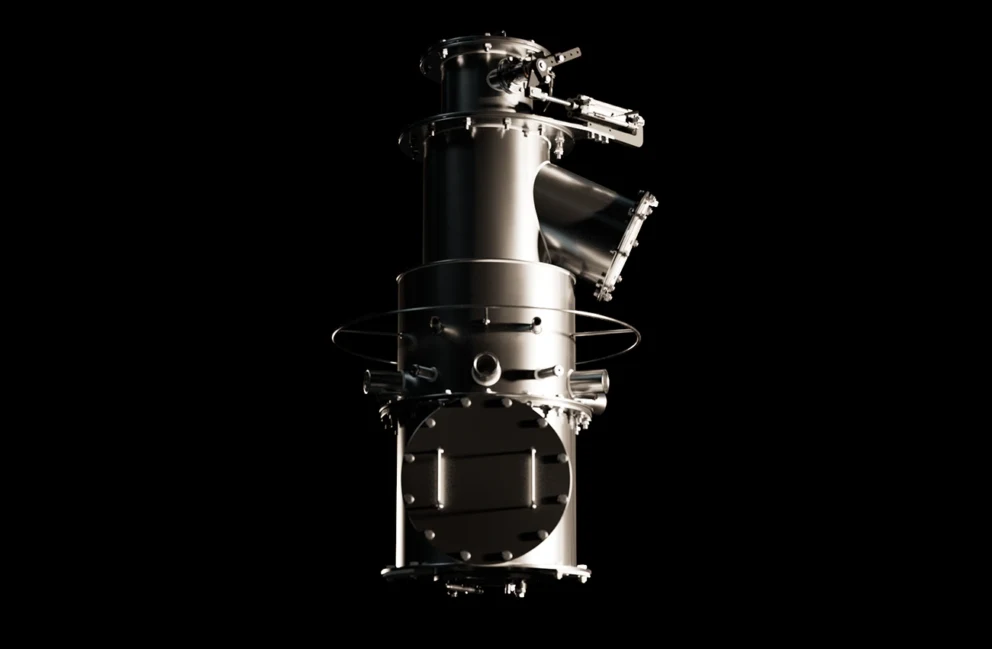

How the CHiP50 works

- Dosage: the dry biomass is directed into the system by a precision feeder.

- Introduction into reactor: the biomass enters the reactor at high temperature, initiating the conversion process.

- Production of biochar: inside the reactor, the biomass is transformed into a mixture of gas and carbon (biochar).

- Separation and use of gas: the mixture is cooled and separated, and the gaseous part fed to the internal combustion engine for the production of electricity.

- Heat recovery: excess heat generated by the process is recovered and made available for other functions of the system, such as drying the biomass at the infeed stage.

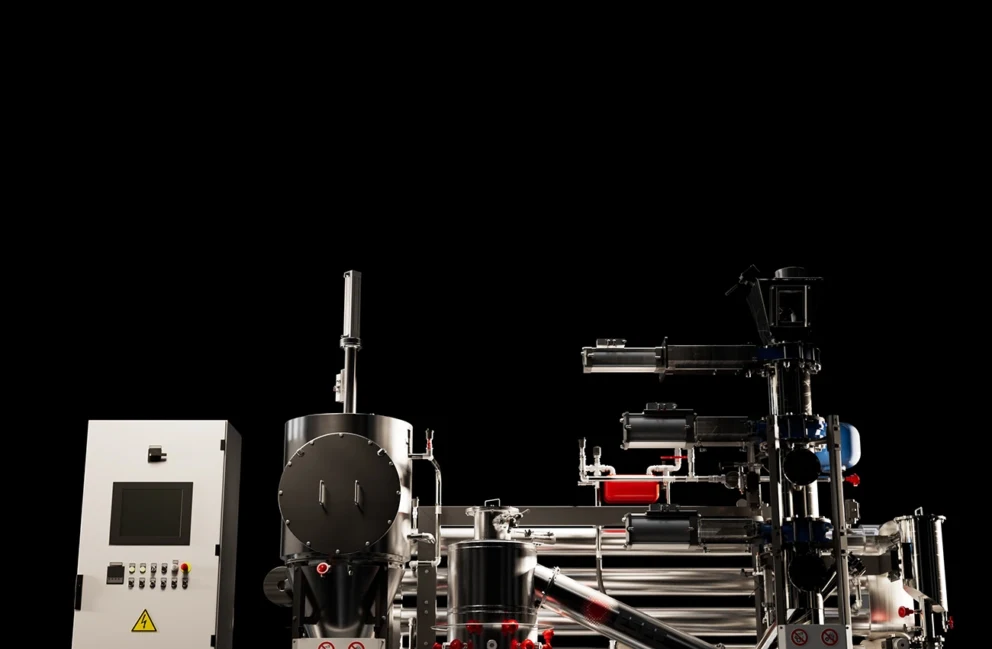

Efficiency, power and savings

The CHiP50 is designed to give maximum efficiency by providing a system that combines electrical and thermal power in a single, compact solution. With an electrical output capacity of 49 kW, the CHiP50 cogenerator offers the perfect power source for factories, light industrial concerns and agricultural businesses, providing a continuous supply of electricity even in off-grid mode.

At the same time, the 110 kW thermal output delivered by the CHiP50 comfortably meets the demand for heating and running hot industrial processes, such as drying equipment and other high-efficiency systems. The wide operating range of the CHiP50 also means that it can run continuously even at low ambient temperatures, making it an extremely reliable solution for users requiring a steady and uninterrupted supply.

Advantages of the CHiP50 system

- Designed for continuous duty in whatever ambient conditions

- Maintenance intervals optimized to ensure less downtime

- Product manufactured entirely in-house to exacting quality standards

- Large displacement engine for long service life and consistent performance

- High thermal and electrical output, for maximum efficiency

- The ideal solution for users seeking reliability and low operating costs

Environment-friendly energy.

Since the CHiP50 uses clean, plentiful and inexpensive biomass, it has a low environmental impact. With this cogenerator, renewable energy can be produced without increasing CO2 emissions and without having to depend on fossil fuels. Using woody biomass also has the effect of keeping forest habitats healthy. Moreover the CHiP50 does not use a combustion process, but one of pyrogasification, which minimizes greenhouse gas emissions, making the best use of natural resources sustainably.