Research and development

Our in-house engineering division has collaborated with various institutions — the University of Padua, the Polytechnic of Milan, the University of Naples, the University of Trento, the University of Edinburgh and the University of Thessaloniki (Greece) — on the design of technologies and energy solutions featuring a high level of efficiency and innovation.

Industrial production

Our manufacturing facilities are equipped with state-of-the-art machinery, enabling us to produce technologically advanced solutions for a number of applications, including turbines for small-medium wind power installations, biomass cogenerators and electrical substations of the latest generation for large photovoltaic systems.

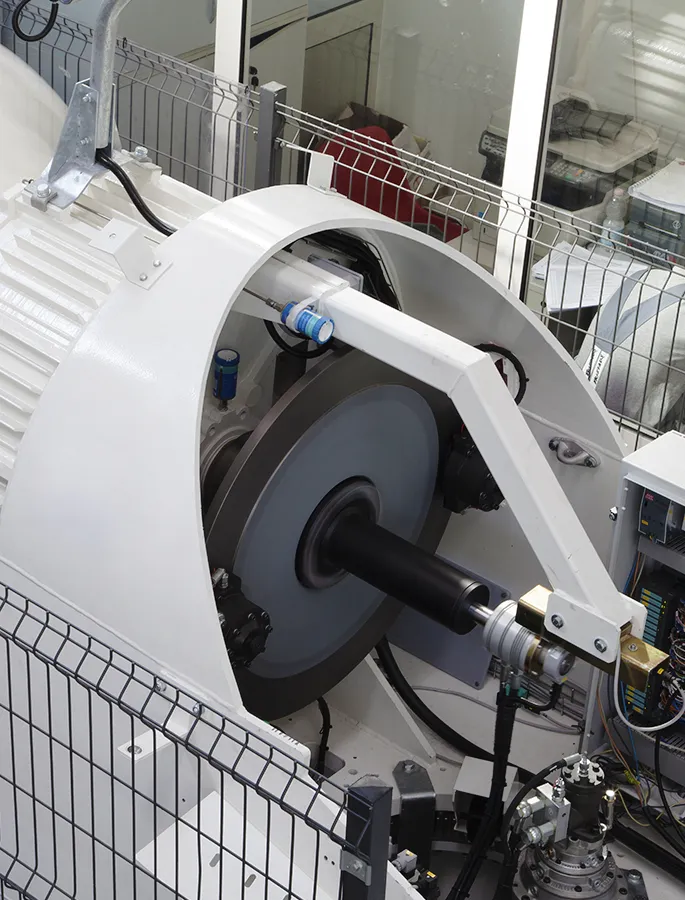

Quality control and testing

To ensure the energy solutions provided to our customers deliver top level performance and long-term reliability, every component we make is inspected and checked in our testing department, applying stringent verification criteria. Technologies are tested in practice by simulating the most extreme conditions for analysis, evaluation and optimization.

Logistics management

Energy technologies involve the application and deployment of typically large and bulky components. We provide efficient and comprehensive logistics management, designing the tailor-made solution that meets both the specific structural requirements of the project and the conditions at the installation site.

Ask for a consultation